Purpose of the flight and payload description

The objective of the flight was to obtain samples of ambient air at different altitudes in the troposphere and low stratosphere using a balloon-borne cryogenic air sampler. The instrument was developed by the Indian Space Research Organization (ISRO) as part of a program led by the Physical Research Laboratory (PRL), Ahmedabad to study the vertical distribution of various trace source gases over India.

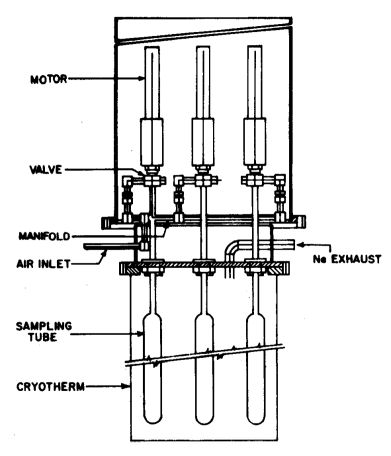

In the image at left we can see an scheme of the cryosampler (click to enlarge). It consisted of sixteen electropolished, vacuum backed, stainless steel tubes with a volume of 400 ml each. Since the trace gases in the stratosphere are in very low concentration levels (parts per trillion by volume, pptv), the quality of tubes play an important role in the measurements. To remove impurities even at very small scale, each tube was baked several times at high temperature and high vacuum.

All the sampling tubes were assembled on a common manifold and each connected to bellow-sealed stainless steel Nupro valves which could be operated simultaneously at high vacuum and high pressure. The manifold was also connected to a ~2 meters air intake tube to avoid contamination of the samples due to degassing of the balloon gondola. Each valve was drived by a DC motor which ensured proper torque for leak tight closure. The manifold was kept on an interface which was attached to a dewar of 25 litres of capacity so that tubes were immersed in liquified neon (-246°C).

A constant pressure of 1.5 bar was maintained inside the dewar throughout the flight using a safety release valve. This motor valve assembly was enclosed in a thermally insulated, double walled chamber and was covered with an insulating transparent perspex plate on the top with O-rings to avoid the ambient cool air circulation. A hermetically sealed 50-pin connector was mounted on the plate which carried power for all the sixteen motors and thermistor connections. Cryosampler was completely enclosed in a specially designed light weight aluminium cage that allowed proper handling of the device during integration and also prevented any damage to the unit at landing. The sampler valves were operated by using a cryo-control unit that basically generated telecomannded signals to open or close the valve of the desired sampling tube.

Details of the balloon flight

Balloon launched on: 4/18/1998 at 4:00 ist

Launch site: TIFR National Balloon Facility, Hyderabad, India

Balloon launched by: National Balloon Facility, Tata Institute of Fundamental Research

Balloon manufacturer/size/composition: Zero Pressure Balloon Antrix - 146.432 m3

Flight identification number: 438

End of flight (L for landing time, W for last contact, otherwise termination time): 4/18/1998

Payload weight: 560 Kgs

External references

- A study of the atmospheric photochemical loss of N2O based on trace gas measurements Chemosphere - Global Change Science, Volume 2, Issues 3-4, 1 July 2000, Pag. 455

- Balloon Flight Report 1969 -2003 TIFR website (via Archive.Org)

- Mechanical properties of ANTRIX balloon film and fabrication of single cap large volume balloons Advances in Space Research 42 (2008) 1691

2666If you consider this website interesting or useful, you can help me to keep it up and running with a small donation to cover the operational costs. Just the equivalent of the price of a cup of coffee helps a lot.